Polycrystalline diamond compact (PDC)

Polycrystalline diamond compact (PDC) bits were first introduced into the oil industry inthe mid 70's.

Since then, numerous technological design changes have been implemented that have made them an extremely effective tool when drilling in certain formations, most typically homogenous sedimentary rock formations including sandstone, shale, dolomite, and limestone.

PDC cutter has high hardness, wear resistance and great tenacity, widely used for making drill bits / tools for oil, gas, mining, engineering and etc.

PDC bits are an alternative to TC bits and surface set diamond bits, when drilling in non-consolidated and medium hard rock formations such as salt, potash, limestone, and clay stone with no crystalline or chert or similar intrusions PDC Coring Bits with/without face discharge: Good cutting, fast penetration, long bit life in soft / Medium hard rockformations.

In applications where drill bit life is dominated by abrasive wear PCD bits perform in an order of magnitude compared to the lifetime achieved by tungsten carbide bits.

PCD drill bits are particularly suited for abrasive rock conditions where tool life, high penetration rates and consistent drilled hole quality are important.

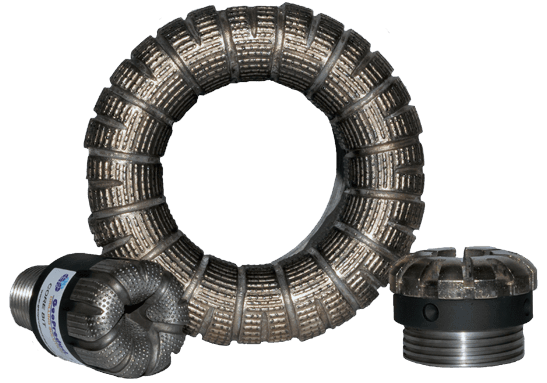

Geoproduct Inc. develop and offers two types of PDC bits.

Diapax bits have brazed round PDC inserts.

Tripax bits have brazed cubic or triangular PDC inserts embedded in the matrix and are recommended for harder sedimentary formations